Cerakote ceramic coating provides a unique appearance and the best corrosion protection

Cerakote is a coating developed in the USA, the land of firearms, specifically for weapons, and is available in many colors and color combinations.

In addition to the desired visual enhancement, the weapon receives a surface that protects against all environmental influences and significantly extends the lifespan of the hunting weapon.

The disassembled weapon parts are cleaned of old bluing or even surface rust in a sandblasting cabinet after a degreasing acetone bath and are recoated with a thin layer of Cerakote in the colors of your choice. This durable ceramic coating from the USA achieves its final strength by baking for two hours at 120°C in a special kiln.

Cerakote not only offers the best corrosion protection but also gives a distinctive look, enhancing the value of your weapon. From sophisticated elegance to post-apocalyptic styles, we can color your weapon exactly to your specifications.

Cerakote Tests

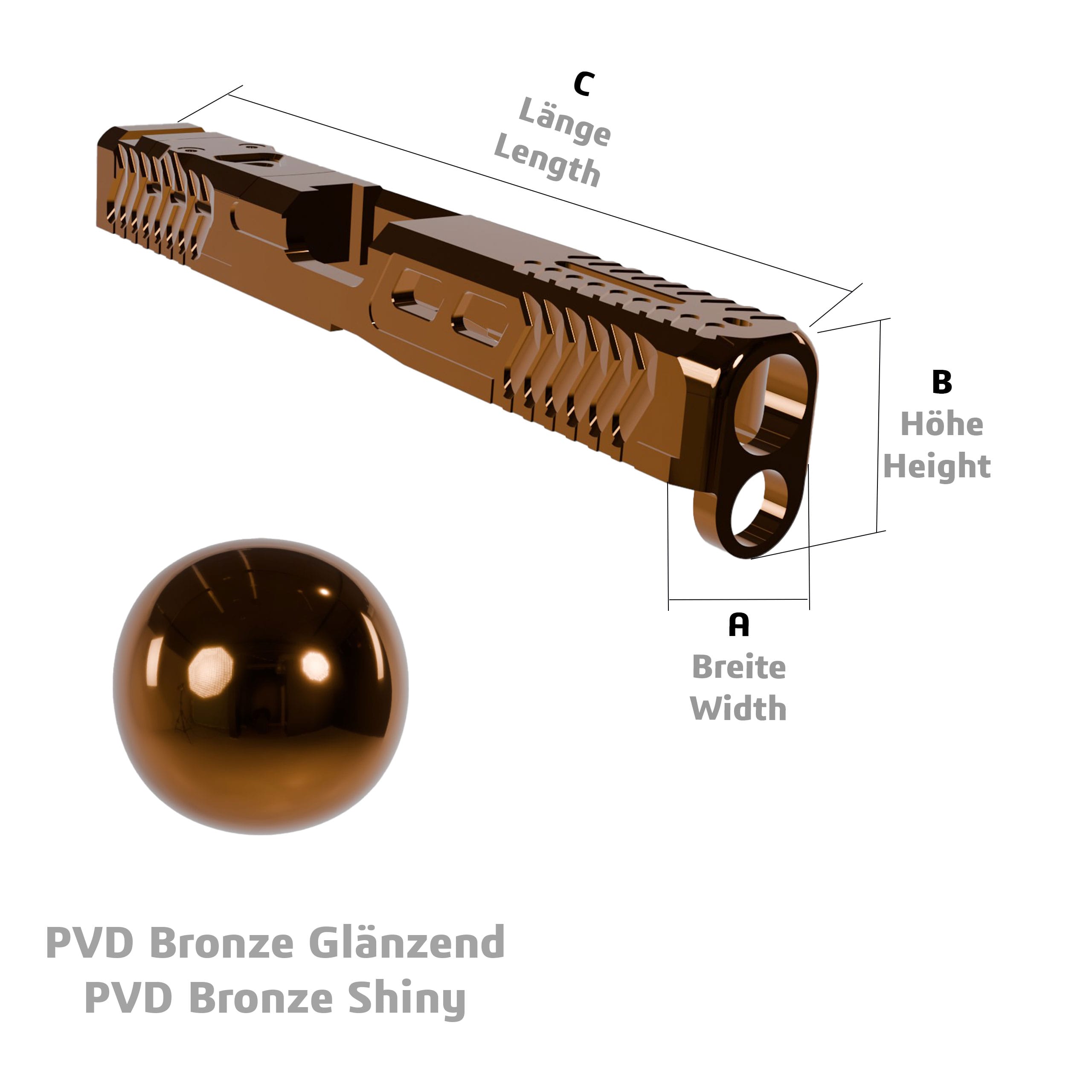

PVD – Physical Vapor Deposition

Physical Vapor Deposition (PVD) is a high-performance coating known for its excellent lubricating properties and extremely high abrasion resistance.

In a highly complex thermo-electrolytic process, particles of molecular size are deposited from carrier plates, which bind to the workpiece to form a protective and visually flawless surface.

The thin layer thickness reflects the pre-treated surface of the workpiece: blasted parts appear matte after coating, while polished parts subsequently shine in the coated color.

Unlike Cerakote, however, the color selection for PVD is quite limited:

- Gold

- Copper

- Silver-gray

- Bronze

Due to the high temperatures of 450°C in the kiln, PVD coating is only suitable for steel parts and, if significant weapon components (such as the barrel or bolt) are coated, a subsequent new proof testing at the proof house is required.

DLC – Diamond Like Carbon

Diamond Like Carbon (DLC) is, as the name suggests, the hardest coating available, with a surface hardness close to that of diamond.

It is perfectly suited for heavily used sports weapons or daily use (e.g., frequent holstering and drawing).

Only the color black can be achieved with this coating. Due to the relatively lower temperatures of up to 190°C during the coating process, it can be applied to aluminum, steel, and stainless steel without requiring new proof testing.

The surface after coating closely reflects the pre-treatment. Sandblasted parts appear matte, peen blasted parts semi-matte, and polished parts retain their level of gloss with only minimal matting from the DLC layer.

By combining differently treated surfaces, brilliant effects can be achieved despite the color limitation.